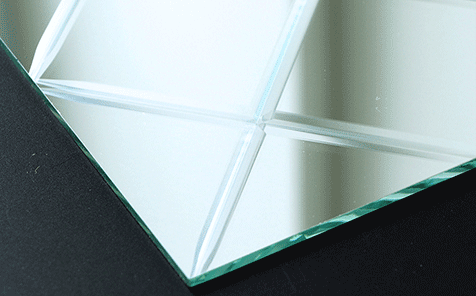

This method involves transferring distinctive images and patterns onto glass or other flat solid surfaces utilizing a UV printer. UV printing on glass ensures both superior quality and longevity.

Advantages

- High-Quality Outputs: Enjoy vibrant and detailed designs on various surfaces including glass and furniture panels.

- Swift Process: Save time with a quick printing process that requires no drying time, ideal for urgent projects.

- Material Versatility: Experience the flexibility of using UV printing on different hard surfaces such as plastic and decorative stone, catering to diverse project needs.

- Long-lasting Prints: Benefit from UV-resistant prints that withstand environmental elements, preserving the quality over time.

Advantages

Rich, Detailed Imagery:

This method can handle full-color printing, facilitating the creation of designs that are both intricate and vibrantly multicolored.

Versatility in Glass Types

UV printing can be employed on a variety of glass types, ranging from large panels for elaborate installations to smaller pieces for personalized souvenirs, making it a flexible choice for diverse projects.

Quick Production Time

Leveraging UV light to cure the ink not only ensures a faster printing process but also means that projects can meet tight deadlines without compromising on quality.

Possibilities

| UV printing (MIMAKI) | |

|---|---|

| Min glass size (mm) | 10×10 |

| Max glass size (mm) | 1300×2500 |

| Glass thickness (mm) Min/Max | 1/50 |

| DPI | 700/1200 |

| Colors | CMYK + WHITE + PRIMER + CLEAR |

| Format | JPEG, PNG, TIFF |

Application Methods

Souvenirs

Pictures