Under our Glass Processing services, we offer glass tempering - a critical process that significantly enhances the glass's resilience and safety features.

About the Process

Glass tempering is a thermal treatment that amplifies the glass's resistance to impacts. Post-tempering, the glass exhibits a heightened strength, being 5-6 times more robust compared to its untempered state.

A notable safety feature of tempered glass is its breakage pattern; it shatters into small, dull fragments, substantially reducing the risk of injury.

*Please be advised that once the glass undergoes the tempering process, it can no longer be subjected to cutting or any other forms of modification.

Glass Tempering Services

Glass tempering is a thermal treatment that amplifies the glass's resistance to impacts. Post-tempering, the glass exhibits a heightened strength, being 5-6 times more robust compared to its untempered state.

A notable safety feature of tempered glass is its breakage pattern; it shatters into small, dull fragments, substantially reducing the risk of injury.

*Please be advised that once the glass undergoes the tempering process, it can no longer be subjected to cutting or any other form of modification.

Advantages

Protects against Injuries from Glass Breakage

The glass is heated to a specified temperature, maintained at that temperature for a period, and then rapidly cooled, undergoing the process of tempering. This makes the glass stronger and more durable compared to regular glass.

Resistance to Thermal Shock

Tempered glass is frequently used in environments where it might be subjected to abrupt temperature changes, such as in car windows, oven doors, and sauna doors or partitions.

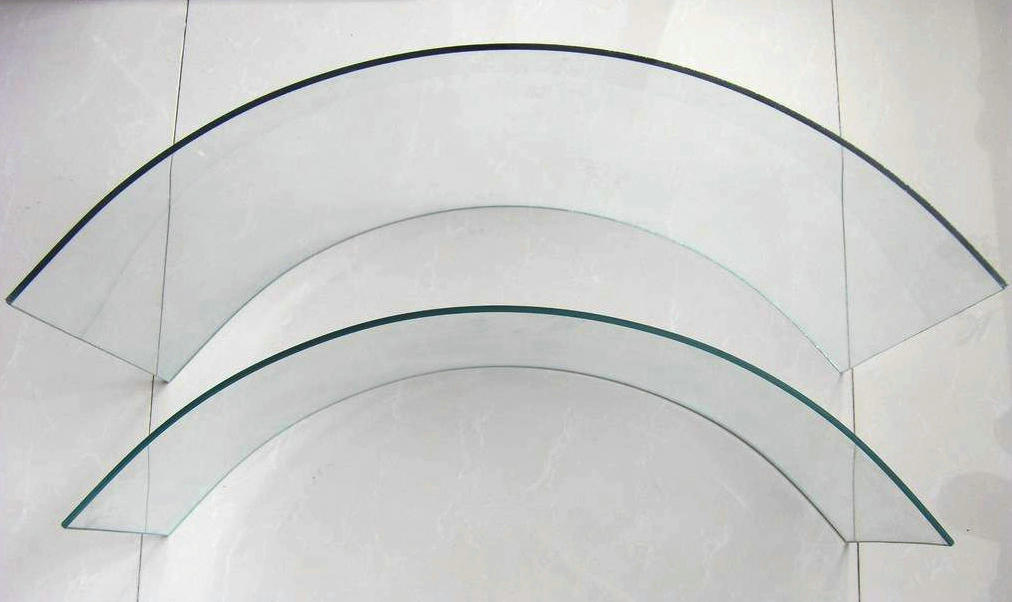

Flexibility

Architects can utilize tempered glass in a wide array of projects. Its flexibility makes it an ideal material for use in glass structures, stairs, and floors.

Possibilities

| Glass thickness (mm) | Glass size (mm) | Min glass size (mm) | Min glass size for round glass (mm) |

|---|---|---|---|

| 4 | 1700×2300 | 240×100 | 250 |

| 5 | 1700×3300 | 240×100 | 250 |

| 6-19 | 2400×4800 | 240×100 | 250 |

Marking of tempered glasses EN 12600 standard

| Glass thickness (mm) | Class according to EN 12600 |

|---|---|

| 4 | 1(C)2 |

| 6 | 1(C)2 |

| 8 | 1(C)2 |

| 10 | 1(C)1 |

| 12 | 1(C)1 |