Ceramic printing is a modern technique that blends the durability of ceramic paints with the adaptability and high-quality output of digital printing.

This method offers a noticeable advantage over traditional screen printing, making it the preferred choice for various reasons, including quicker production time, superior aesthetic appeal, and better quality of the end product.

Utilizing advanced digital technologies, we can quickly and easily transfer designs or artworks onto glass surfaces using straightforward digital files. This method is especially effective in achieving outstanding results on building facades that are exposed to outdoor elements.

Advantages

• Durability: Ceramic paints can withstand UV rays and other adverse environmental conditions, such as extreme weather and temperature variations.

• Versatile Glass Decoration: Ceramic printing allows for the seamless transfer of graphical images, vector illustrations, or photographs onto glass surfaces.

• Aesthetic and Functional: This method offers distinct decorative opportunities for both interiors and exteriors. Specific patterns can enhance privacy, increase thermal insulation, and regulate sunlight penetration.

• Flexibility: This technique accommodates the creation of unique, custom products as well as bulk production, catering to the needs of both individual and corporate clients.

Application

Doors, partitions, stair railings, shower glass, balcony railings, interior and exterior wall decor.

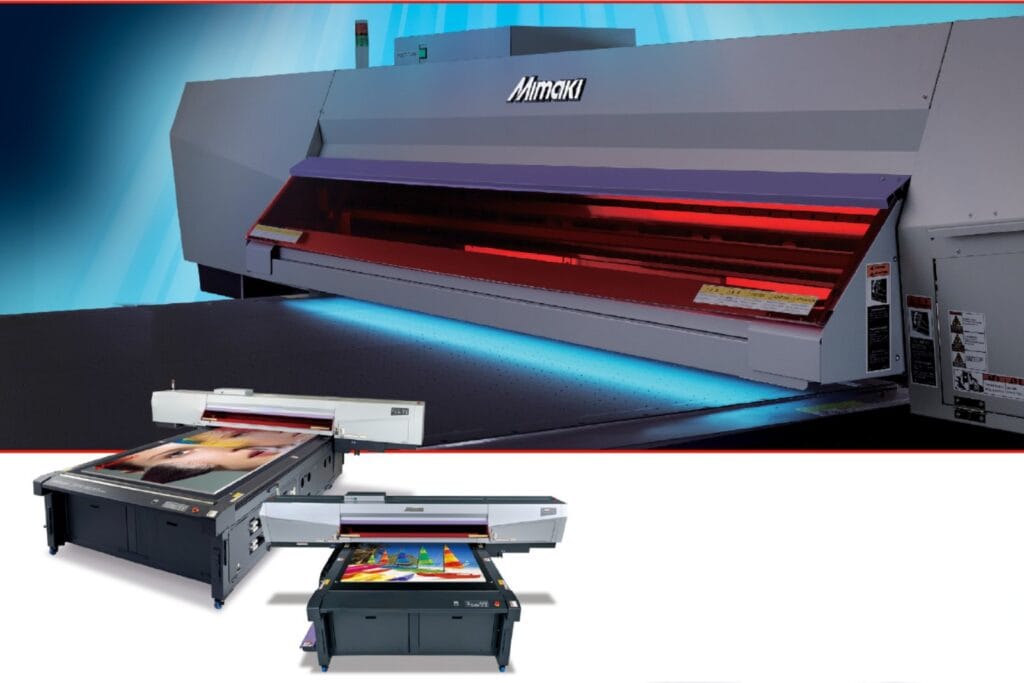

Digital Ceramic Printing Processing

Standard Glass Processing

This phase encompasses all the necessary procedures requested by the client, including cutting, grinding, and drilling, among others.

Graphic File Processing

We refine the high-resolution files supplied by the client or suggested by our designer using specialized software, ensuring they are optimized for printing.

Tempering

Following the printing process, the glass undergoes a tempering process, which ensures the imprinted image retains its quality over time, unaffected by direct UV rays or environmental factors. Utilizing extra clear glass is recommended for superior color fidelity.

Quality Assurance and Delivery

After the printing stage, each glass piece is meticulously inspected to guarantee its quality before being securely packaged for delivery.

Possibilities

| Digital Ceramic Printing (DIP-TECH) | |

|---|---|

| Min glass size (mm) | 400×480 |

| Max glass size (mm) | 2400×1700 – 4 mm 2400×4800 – 6-19 mm |

| Glass thickness (mm) Min/Max | 4/19 |

| DPI | 720 |

| Colors | WRBOGB |

| Graphics file formats | PS, EPS, DXF, DWG, DWF, TIFF, BMP, JPEG |

Application Methods

Glass decorated with ceramic printing finds its usage in crafting railings, showcases, facades, partitions, and various other glass structures.

Glass door

Showcases

Facades

Shower Glass